|

| |

TM 9-2350-287-20-2

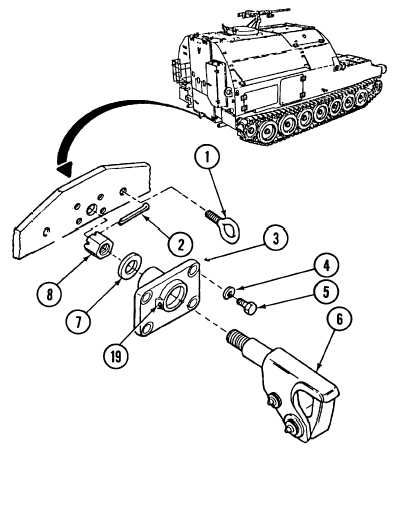

13-2. TOWING PINTLE REPAIR (continued).

e.

1.

2.

3.

4.

5.

6.

7.

8.

9.

INSTALLATION

Coat threads and shaft of pintle body (6) with grease.

Install pintle body (6) on bracket (3).

CAUTION

Do not overtighten slotted nut. Pintle body must rotate freely in bracket. Failure to

heed this caution may result in damage to pintle body or bracket.

Install bearing (7) and slotted nut (8) on pintle body (6). Tighten slotted nut (8) only enough to take up any

space between bearing (7) and bracket (3).

Back off slotted nut (8) until hole in shaft of pintle body (6) alines with slots on slotted nut (8).

Install new cotter pin (2) in slotted nut (8).

Install bracket (3) on rear of vehicle with four screw (5) and new Iockwashers (4).

Apply grease at fitting (19) to fill bracket (3).

WARNING

Sealing compounds can

burn easily, can give off

harmful vapors, and are

harmful to skin and

clothing. To avoid injury

or death, keep away from

open fire and use in a

well-ventilated area. If

sealing compound gets

on skin or clothing, wash

immediately with soap

and water.

Coat threads on two eyebolts (1) with sealing

compound.

Install two eyebolts (1 ) in rear of vehicle.

FOLLOW-ON MAINTENANCE:

• None

13-5

|